At Peak, we pride ourselves on our design, engineering and innovation expertise.

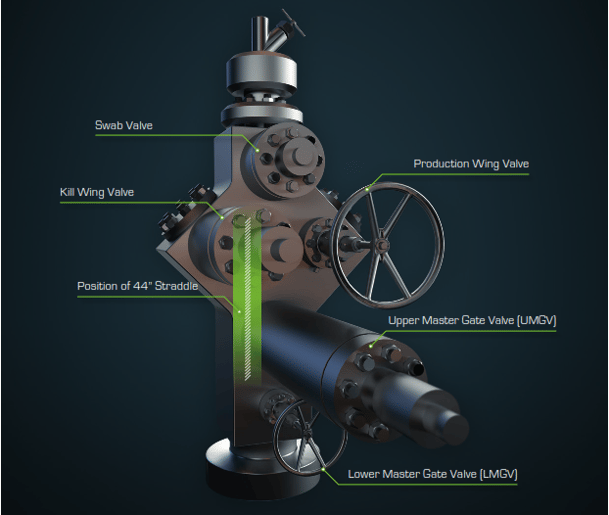

Recently, a customer approached Peak to design an innovative straddle solution to anchor and seal in a production X-tree above and below a leaking Upper Master Gate Valve (UMGV) Stem Seal to allow repairs to be undertaken.

The straddle was required to sit above the top of the Lower Master Gate Valve (LMGV) and below the bottom of the Swab Valve without causing damage; and it could not exceed 44” in length.

A minimum straddle ID of 4.425” was also required by the Customer to enable them to run through and set a plug below the X-tree to isolate the well, and to provide the option to pump through to kill the well to perform a tree change-out in the event repairs could not be completed, or were delayed.

The operation would be subject to a working pressure of 3,000psi, and an in-service temperature rating of 5 to 80degC. The proposed solution was to meet the Customers ISO 14310 V0 specification requirements.

Peak’s Solution

Peak’s engineering team developed a solution to meet all the customer’s requirements within a short time frame; one that would isolate the UMGV to allow repair, and one that was soft set to ensure the LMGV would not be damaged during the operation.

Click the link below to learn more about this straddle solution and how it enabled our customer to efficiently carry out the necessary repairs to the leaking UMGV - minimising extended production loss - and complete the full campaign without having to carry out contingency operations or kill the well.

For more information on how Peak's well barrier and isolation solutions could help your company please contact us.